MOTAN For pellets or powder blending

motan‘s GRAVICOLOR meters and blends up to 6 materials with high accuracy and repeatability. This gravimetric blender is designed for use directly on an injection moulding machine or as a central blending station. With the GRAVICOLOR blender, use of all materials is constantly optimised for efficient and economic performance combined with consistently high product quality. The metered and weighed amounts are constantly checked against the preselected set values by the control. This guarantees exceptionally high accuracy of less than ±0.1%.

Gravimetric or volumetric feeder

MINICOLOR G

(Gravimetric dosing and mixing unit)

Compact gravimetric dosing and mixing unit for one main component and one masterbatch or additive in granular form suitable for injection moulding machines, extruders and blow moulding machines.

With the GRAVInet MC control up to two dosing heads can be operated.

The unit is based on the well tried MINICOLOR concept with gravity mixing funnel guaranteeing a homogeneous material mix and eliminating separation. The dosing head for masterbatch or additive sits on a robust but extremely precise load-cell and operates using loss-in-weight metering technology. This offers operational security for high level requirements.

MINICOLOR G A enables easy addition of regrind. Due to automatic calibration, the commissioning time is extremely short. The MINICOLOR G is insensitive to vibrations and is specially designed for mounting directly onto the feed throat of the processing machine

MINICOLOR V

(Volumetric dosing and mixing unit)

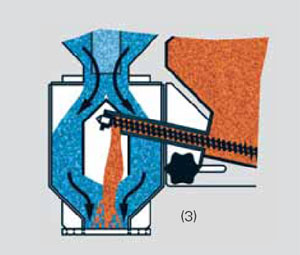

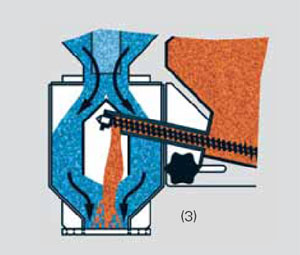

Mounted between the machine hopper and the feed throat of the plastics processing machine the MINICOLOR requires very little space. A stainless steel cruciform in the mixing throat divides the main component into two streams of material. They flow together with the additives at the feed inlet producing a homogeneous mixture.

For powder volumetric feeding and blending

C-FLEX M VOLUMETRIC

(Dosing unit with flexible walled hopper)

motan's C-FLEX is designed to offer the greatest flexibility in flexible-walled feeder design and construction. C-FLEX is ideally suited for dosing powders, pellets, granulates, regrinds, fibers, and flakes in both continuous and batching processes. motan's unique removable flexible hopper provides two huge advantages over traditional feeder designs. Firstly, the quick exchange hopper enables the user to clean and change materials in less than one minute.

Secondly, single and twin screw hoppers are interchangeable, allowing the user to configure the feeder for nearly any type of material in a matter of minutes. In addition to high flexibility, high performance is assured since consistent screw fill is maintained and bridging eliminated through the use of a flexible polyurethane hopper that is activated by friction-free massaging rolls. The C-FLEX can be integrated into both gravimetric and volumetric systems. Its modular design enables the user to upgrade the system easily and cost effectively.

GRAVIBLEND for powder

(Gravimetric dosing system)

GRAVIBLEND is a continous gravimetric feeding and blending system that meets the most sophisticated demands for homogeneity and is designed for 24-hour continuous, maintenance-free operation.

GRAVIBLEND functions according to the loss-in-weight principle. This means that each individual component is being fed in absolute weight values in relation to weight. Continuous operation coupled with synchronous material feed ensures true-to-formula constant blending ratio in the collecting hopper at all times.

Applications for complex continuous production processes in extrusion, such as textile fibre, chemical fibre, master batch, foam sheeting and multilayer special sheeting, as well as all applications with highly complex compound precision requirements. Component feeding is being carried out continuously. The material flow is being monitored continuously and controlled in relation to weight by a weighed collecting hopper.

GRAVIBLEND can be used for flow rates from 0.2 to 1200 dm³/h (at a bulk density of 0.5 kg/dm³) per station and for free-flowing plastic granules with product temperatures up to max. 180 °C. (Observe design guidelines) The typical maximum flow rate of 1500 kg/h per line should not be exceeded. GRAVIBLEND models are available with max. 4 or 8 dosing stations.

GRAVIBLEND is manufactured in accordance with "CE" specifications.