machines à injection

ARBURG is one of the leading global manufacturers of injection moulding machines. Robotic systems, complex production cells and other peripherals are also included in our product range.

All of our injection molding solutions are in line with our company philosophy, which defines ARBURG as a partner for efficient injection moulding.

In order to provide our customers with first-class support, we have a global sales and service network: ARBURG is represented by its own organisations in 24 countries at 32 locations and by trading partners in more than 50 countries

Lossburg headquarters

Lossburg headquarters

The company's success confirms this to be the correct approach. That is why ARBURG exists in precisely this form: some 1,680 employees at the parent factory in Lossburg covering some 146.000 square metres of floorspace. Ultra-modern production facilities which are continuously brought up-to-date through investment in the latest machine technology. Development and design departments which work today on the technologies of tomorrow and beyond. Comprehensive IT networking, enabling full utilisation of the productivity advantages. A modular machine and peripherals range allowing customers to procure a technological solution precisely tailored to their production requirements. All this always at the best-possible price/performance ratio. The company's support offering also ensures that optimum use can be made of the high-quality products and that assistance is always provided where it is required.

Arburg Machines

Arburg Machines

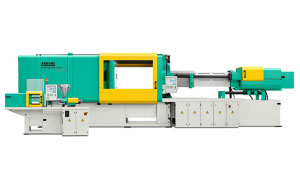

MACHINES

The ARBURG machine range includes the ALLROUNDER A, E, GOLDEN EDITION, H, S, T and V series. This provides the opportunity to put together an individually equipped machine from the extensive options available, for example with respect to clamping force, injection unit, screw diameter or axis drives.

The use of ALLROUNDER injection moulding machines extends far beyond the field of standard applications. Thanks to the various equipment versions, the ALLROUNDERs can also be utilized in a modular manner for special processes and applications.

Example of sequence of programming a production cycle

Electric

Allrounder E

The ALLROUNDER E (EDRIVE) machines are entry-level models into the world of ARBURG electric machines. They are particularly suitable for the effective production of technical parts. The electric EDRIVE machines cover a clamping force range from 600 to 2.000 kN.

In our ALLROUNDER E machines, direct-acting play-free spindle drives ensure mechanically rigid drive axes and correspondingly dynamic movements. High-resolution, contactless position measurement by an absolute position encoder in the motor makes movement to a reference position unnecessary. The excellent positioning accuracy of all servo-electric drives permits maximum reproducibility and part quality.

Allrounder A

The ALLROUNDER A (ALLDRIVE) are ARBURG’s electric injection moulding machines for high-end injection moulding applications The electric ALLDRIVE machines cover clamping forces from 350 to 3,200 kN.

In our electric ALLROUNDER machines, direct-acting play-free spindle drives ensure mechanically rigid drive axes and correspondingly dynamic movements. High-resolution, contactless position measurement by an absolute position encoder in the motor makes movement to a reference position unnecessary. The excellent positioning accuracy of all servo-electric drives permits maximum reproducibility and part quality.

Hybrids

Allrounder H

The ALLROUNDER H (HIDRIVE) are hybrid high performance injection moulding machines and cover a clamping force range from 600 kN to 5,000 kN. They offer maximum production capacity with short cycles and reduced energy consumption.

ALLROUNDER H injection moulding machines feature energy-efficient drive technology and achieve maximum performance in the field of thermoplastics processing with short cycle times. In this HIDRIVE machine series, the best from the ARBURG modular component system was combined, to bring a high-quality machine concept.

The combination of

- the servo electric clamping unit from the ALLROUNDER A

- the hydraulic injection unit from the ALLROUNDER S advance

- and performance-adapted hydraulic accumulator technology from the ALLROUNDER S

results in a highly sophisticated machine series with high functionality.

With the ALLROUNDER H, ARBURG offers a powerful combination of electric and hydraulic machine technology.

Hydraulic injection moulding machines

Allrounder S

The ALLROUNDER S machines are multi-purpose hydraulic injection moulding machines for all applications and can be expanded from basic models through to high-tech machines. They are available in a clamping force range from 125 kN to 5,000 kN.

ALLROUNDER S machines are a versatile hydraulic series from ARBURG, with a performance and universal suitability that enables them to cover the largest range of applications. The modular design of these machines, with several alternative hydraulic and electric options and different equipment versions, allow individual, cost-effective machine solutions. Thanks to their adaptability, not only are ALLROUNDER S machines able to perform a wide variety of different process tasks with all the familiar injectable materials, they can also be equipped in an extremely energyefficient manner. Therefore, machines with electro-mechanical dosage drive (AED) or the “advance” equipment package also bear the ARBURG “e²” energy-efficiency label.

Allrounder Golden Edition

The ALLROUNDER GOLDEN EDITION offers modern machine technology for economical injection moulding production at an attractive price. The ALLROUNDER GOLDEN EDITION machine series covers a clamping force range from 400 to 4.600 kN.

The ALLROUNDER GOLDEN EDITION series consists of hydraulic machines from ARBURG with an unbeatable price/performance ratio. They impressively demonstrate that, thanks to consistent series production and standardisation, the purchase of durable, high-quality injection moulding machines equipped with the latest technology is a cost-effective decision. The extensive, technically high-quality standard equipment of these machines is based on proven ARBURG components and is suitable for processing all common thermoplastics. The standard dual-pump system is further enhanced by fast-switching valves situated close to the hydraulic consumers, highly wear-resistant cylinder modules and SELOGICA ‘direct’ machine control system with 15-inch touchscreen.

Vertical machine

Allrounder V

The ALLROUNDER V machines with fixed vertical clamping unit are designed as free-space systems and predestined for encapsulating inserts.

The ALLROUNDER V series comprises compact vertical machines from ARBURG, designed specifically for the encapsulation of manually introduced inserts or for integration in automated production lines. The free-space system in the area of the clamping unit and the low table heights with fixed mounting platen positioned at the bottom ensures comfortable ergonomic working. The injection units of ALLROUNDER V machines can be set up both vertically and horizontally for injection into the parting line. Different screw geometries and wear-resistance categories are available, enabling the use of a wide range of injectable materials such as thermosets and silicones, for example. Flexibility is further enhanced by rotary or sliding tables.

Allrounder T

The ALLROUNDER T machines are vertically operating rotary table machines for high-volume encapsulation of inserts.

The ALLROUNDER T series comprises vertical rotary table machines from ARBURG, specially designed for the automated encapsulation of complex inserts. What makes them impressive is their modular design with several alternative hydraulic and electric expansion stages and different equipment versions. With this series, individual, cost-efficient configurations can be achieved. As the tie bars are positioned outside the table diameter, the rotary table provides a generous amount of free space for securing the moulds. This makes the ALLROUNDER T machine series perfectly suited to the often highly specialised injection moulding requirements that characterise this particular segment today.

Robotic Systems

ARBURG offers its customers machines and robotic systems from a single source. The machine is programmed and controlled via the central SELOGICA control system. A high degree of convenience is guaranteed here both by virtue of the operating principle with schematic sequence programming and the option of saving the respective MULTILIFTs integrated data record together with that of the mould.